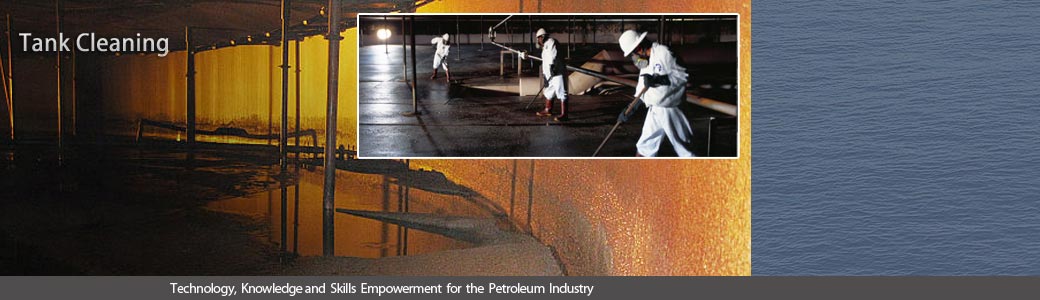

Petroleum Storage Tanks Cleaning & Sludge Removal

Crude Oil Tank Sludge Removal and Storage Tank Cleaning

Tank Cleaning & Turn Around Maintenance TAM Services for the following:

Petroleum

♦ Crude Oil Tank Farms

♦ Product Terminals

♦ Refineries

Power Plant Tanks

♦ Power generating facilities

♦ Petroleum Marketers

♦ Other Downstream

Industrial Tanks

♦ Factory Tanks

♦ Manufacturing entities

♦ Downstream facilities

We are the leader in the Petroleum Crude Oil Tank bottom sludge removal and Storage tanks cleaning. We thoroughly clean crude oil storage tanks of any size and remove all the sludges and sediments present. We also recover the crude oil for you.

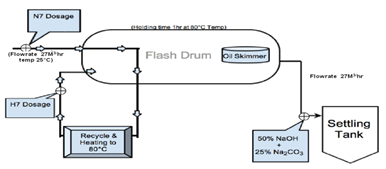

Our patented technology uses Natural environmental friendly Green chemical to break emulsions and improved separation. Our Technology eliminates the use of water injection in the sludge and prevents emulsion building. Crude Oil Tanks are thoroughly cleaned free of any sludges, sediments or solids.

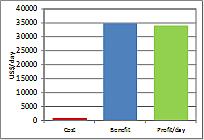

Apart from removing the sludges, we also recover more than 95% of any crude oil contained in the sludge and sediments in the tanks. The recovered oil has high economic value. The high quality recovered oil can be returned into the process or sold as high value oil.

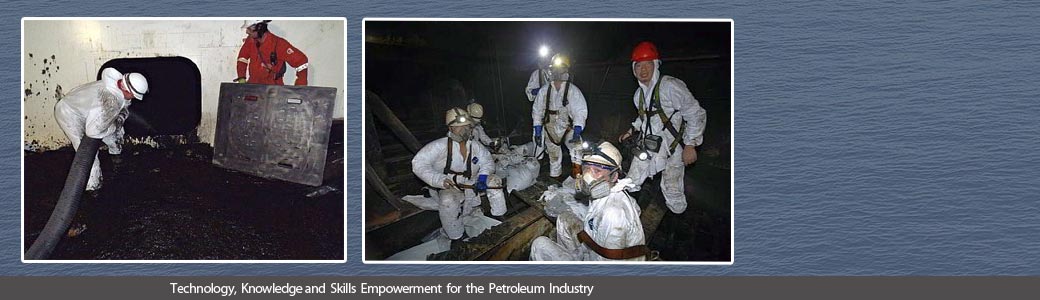

Our operations are safe, require no man-entry into the tanks, except for final manual inspection of work done and removal of any final centimeters of residual sediments. The tanks are jet washed and cleaned to a "hot works" US API inspection standard, and our service comes with guarantee of fast treatment and reduction of tank Downtime.

Right from start, we perform dipping and sludge sampling, and provide you with accurate estimate of total sludge volume present in tank, the amount of recoverable crude oil present, along with other reports concerning your storage tanks. We also inform you of how many days we would require to thoroughly clean the tanks out and recover the crude oil for you. Results presented in a detailed report, including project cost.

Crude Oil Tank Sludge Removal and Storage Tank Cleaning

We guarantee:

Natural Environmentally Friendly Separation: Use of Natural environmentally friendly Green chemical with patented 100% Natural Nano technology chemistry and patented Nozzle system to break emulsions and improved separation

High Economic Value Recovered Oil: Recovered oil can be returned into the process or sold as a high value oil. The recovered oil containing 0.5%BS&W can then be returned into the process or sold as high value oil.

High Quantity Recovered Oil: Apart from removing the sludges, we also recover more than 95% of any crude oil contained in the sludge and sediments in the tanks.

High Quality Recovered Oil: Recovered Oil free of sediments. Our technology removes more than 99% to 99.5% sediments, even from sludges pitts originally containing 20% to 50% sediments. This provides High quality recovered oil.

Time Reduction for Completion: Total time reduction, with Faster / better Oil /water Separation, and Less oil in waste water. Fast treatment so reduction of Downtime tank

No Water – No Emulsion Building: Our Technology uses No water injection in the sludge, this avoids any emulsion building up.

Ambient Temperature De-sludging: De-sludging without elevated temperature. This saves energy and ensures safe operations.

Safe Operation: Our patented Nozzle system remains fully submerged under oil/sludge level so safe regarding LEL levels. No nitrogen purge is needed and Air extraction pumps are used during Cleaning process. In addition, it is Environment friendly with less than 100 ppm leachable hydrocarbons in solids.

Accurate Sludge Volume Calculation at Start: Right from start, we perform Manual dipping and sludge sampling, BS&W value, and provide you with accurate estimate of total sludge volume present in tank, the amount of recoverable crude oil present, along with other reports concerning your storage tanks. We also inform you of how many days we would require to thoroughly clean the tanks out and recover the crude oil for you. Results presented in a detailed report, including project cost.

US API Inspection standard: Our operation are safe. Our patented Nozzle system ensures optimum fluidization and sludge pump out so thoroughly, requiring no man-entry into the tanks, except for final manual inspection of work done and removal of any final centimeters of residual sediments via static pump/vacuum suction.. The tanks are jet washed and cleaned to a “hot works” US API inspection standard, and our service comes with guarantee of fast treatment and reduction of tank Downtime

Case Study 1: Summary of Results of a Field Trial conducted in a Gas Terminal

Note: Significant improvement in condensate oil and glycol recovery

Case Study 2: Sludge Breaker In a Refinery

Summary:

Sludge is a 2 year old sludge from a Refinery containing 52% to 85% wax content.

Before Treatment: Without treatment the sludge is only flowable at a temperature of 85-90°C.

After Treatment: The Sludge was treated with our natural environmentally friendly Green chemical with patented 100% Natural Nano technology chemistry.

After the treatment the sludge can be kept and transported at a temperature of 22°C in liquid phase, and is sold as Bunker fuel.

SmartKoncept is The One Stop Total Solution Place for your Training, Manpower Development, Consulting and Procurement in the Petroleum Oil and Gas Industry.

Join Us - Register today Complete Online Contact Form Email Us or Call +1 281-668-5453